Carry Out The Descaling Of A Water Cooled Condenser

The cleaning liquid can be added to the cooling water system in a certain proportion and the cooling pump is turned on for 12 to 24 hours.

Carry out the descaling of a water cooled condenser. Failure to control mineral scale formation in a cooling water system will eventually result in shut down of the plant. Therefore it is necessary that regular quarterly or at least yearly cleaning of chiller tubes is scheduled and carried out. Descaling compound mineral scale forms in the hot parts of the cooling system like heat exchangers and condensers. Even before shut down of the system the build up of.

Scale can form thick deposits on heat transfer areas reducing water flow decreasing heat transfer and causing high head pressure. Water cooled condensers involve a heat rejection loop where condenser heat is dissipated to the environment via water. The presence of scale also forces the system s compressor to work harder. Water cooled air conditioner is also called water cooled condenser as its function is to reject the heat that was absorbed by the refrigerant in the evaporator.

I recently received an email from chris molyneaux of air treatment engineering and maintenance in durban in which he wrote that while getting technical had covered the prevention and control aspects of scaling in water circuits we in the. First check the scaling. This scale can affect the efficiency of water cooled systems and the overall life of the equipment. Reducing the temperature of the water entering the condenser of an industrial chiller significantly improves efficiency as it has to work less to exert its overall cooling.

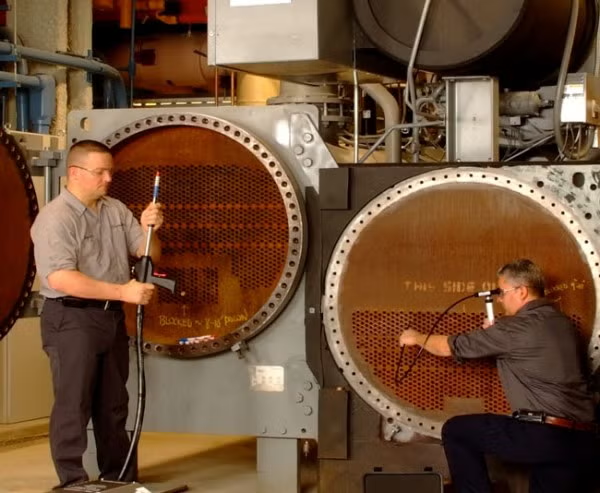

The most common type of water cooled condensers in geothermal power plants are direct contact and surface types. When water is heated or evaporated solid matter called scale often is left behind. It is know as descaling it is to be done when the condenser approach is going high like 3 4 5 c. Water cooled condenser descaling method steps.

We look at the process of removing scale that has already developed in condensers using descaling acidic chemicals. 1 with the condenser heat transfer surface being one of the main four components of a water cooled chiller system on the one hand and the possible reduction of heat transfer capacity in the condenser due to precipitation over the said surfaces on the other the condenser is required to be cleaned regularly every year depending on the properties of the water and the climatic conditions. Reduce the temperature of the condenser water. Plate type heat exchangers a special kind of surface exchanger are also possible but appear to be more common in liquid to liquid heat transfer applications.