Dbb Slab Gate Valve

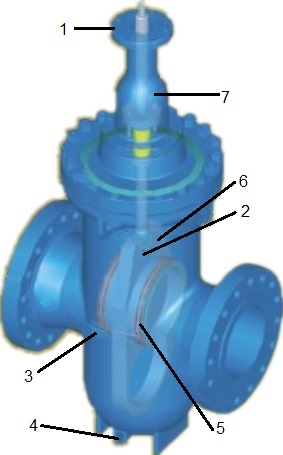

All model c2 sl slab gate valves are manufactured per the latest edition of api 6d requirements they are available in bore sizes ranging from 2 through 36.

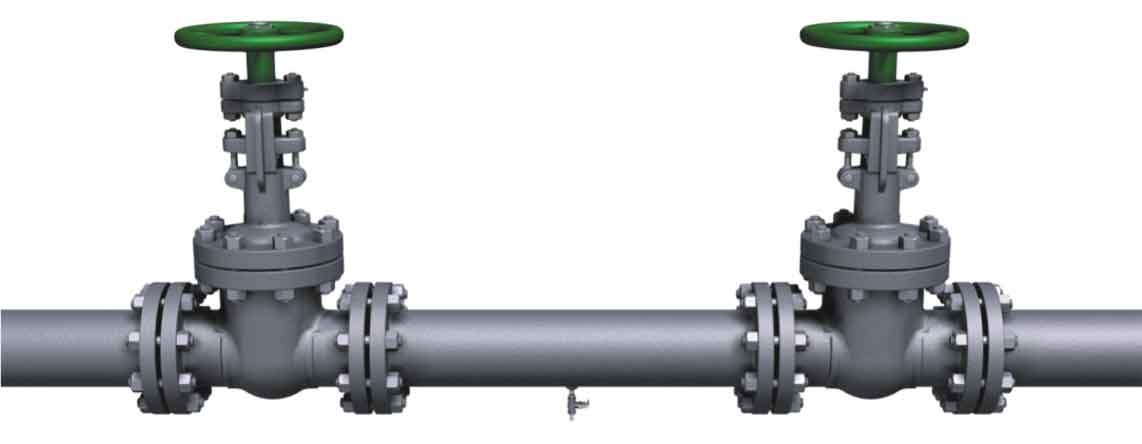

Dbb slab gate valve. The calvary c2 sl slab gate valve is designed for dependable service in the pipeline oil natural gas wellhead applications or other critical services throughout the energy industry in ansi 150 to 1500 class operating pressures. The full bore design has the same pressure drop as an equivalent length of pipe and allows passage of all. Bel valves through conduit expanding gate valve enables double block and bleed dbb functionality to be achieved within one single valve assembly as opposed to the two conventional slab gates that would otherwise be required. There are two entities in the united states that define dbb api and osha.

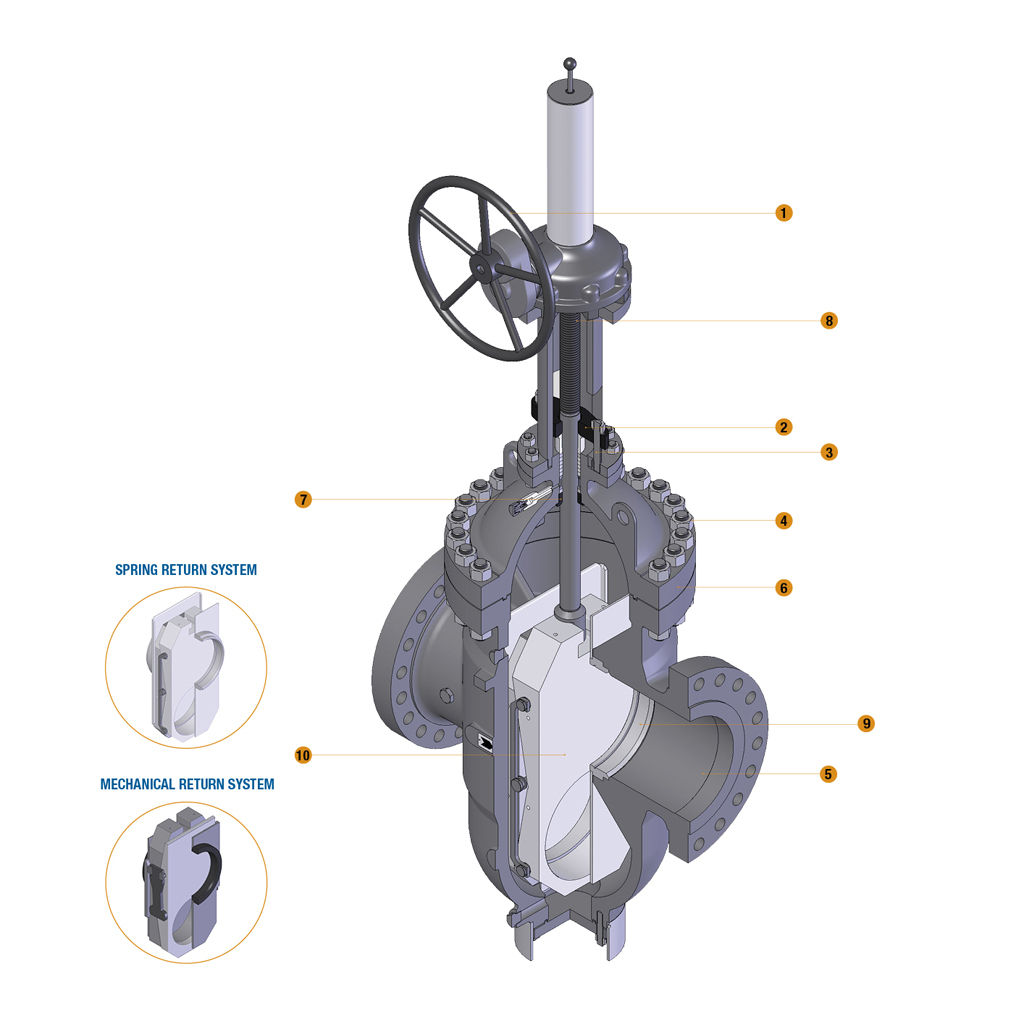

Through conduit dbb slab gate valve through conduit swing check valve dual seal dbb expanding plug valve forged 3 pc bolted body ball valve cast bolted body ball valve welded body ball valve rising stem ball valve top entry ball valve piston check valve lubricated plug valve dual plate wafer check ansi gate globe check valve. Each seat contains a metal seat face plus a peripheral seal. The slab gate valve is a full bore with solid parallel slab gate. According to api a dbb valve is a single valve with two seating surfaces that in the closed position provides a seal against pressure from both ends of the valve with a means of venting bleeding the cavity between the seating surfaces.

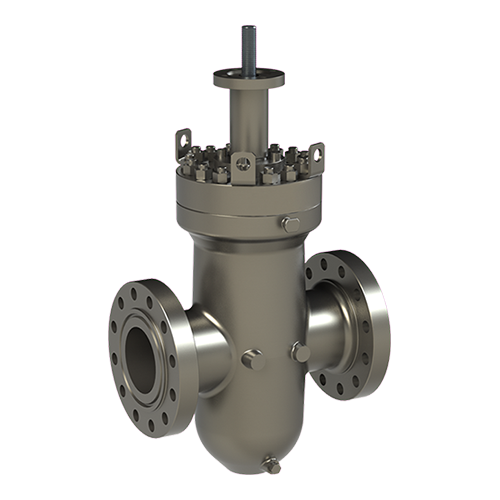

The cameron wkm saf t seal slab gate valve is a simple yet rugged and reliable through conduit valve. It utilizes two floating seats to provide a complete seal with the gate. They are available in bore sizes ranging from 2 through 36. The calvary c2 sl slab gate valve is designed for dependable service in the pipeline oil natural gas wellhead applications or other critical services throughout the energy industry in ansi 150 to 1500 class operating pressures.