Draft Angle Vacuum Forming

What we re going to do here is touch upon design issues that you must think about so that you can avoid issues.

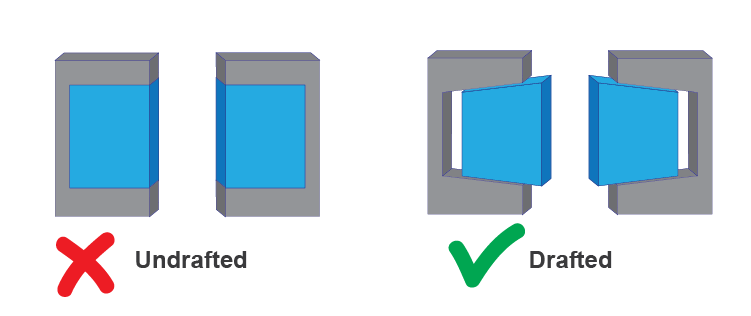

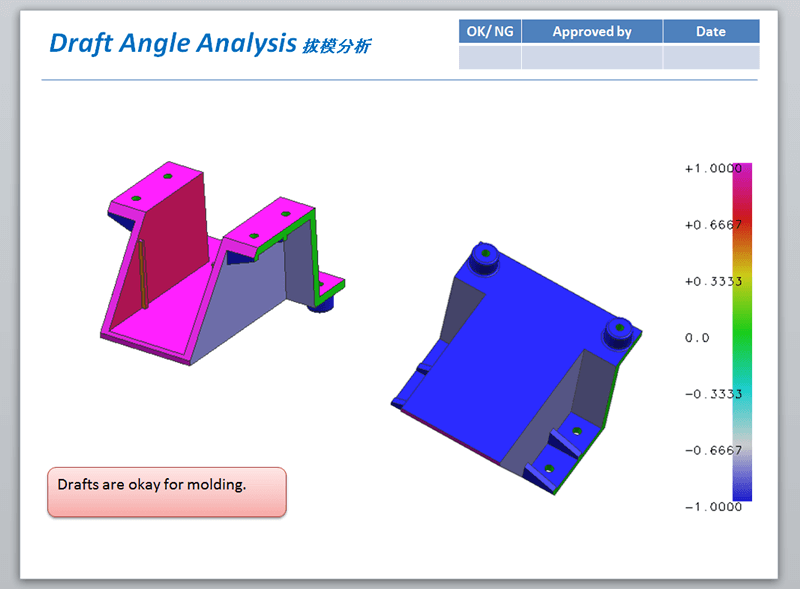

Draft angle vacuum forming. To succeed whilst using it however there are steps you need to follow. The draft angle also plays a role in keeping down the cost of vacuum forming. Normally draft angles are present in the design of the mold a recommended minimum of 3. When designing for the vacuum forming process you must add draft angles to all sides of your parts to ease removal of the plastic parts from the tool once they ve been formed.

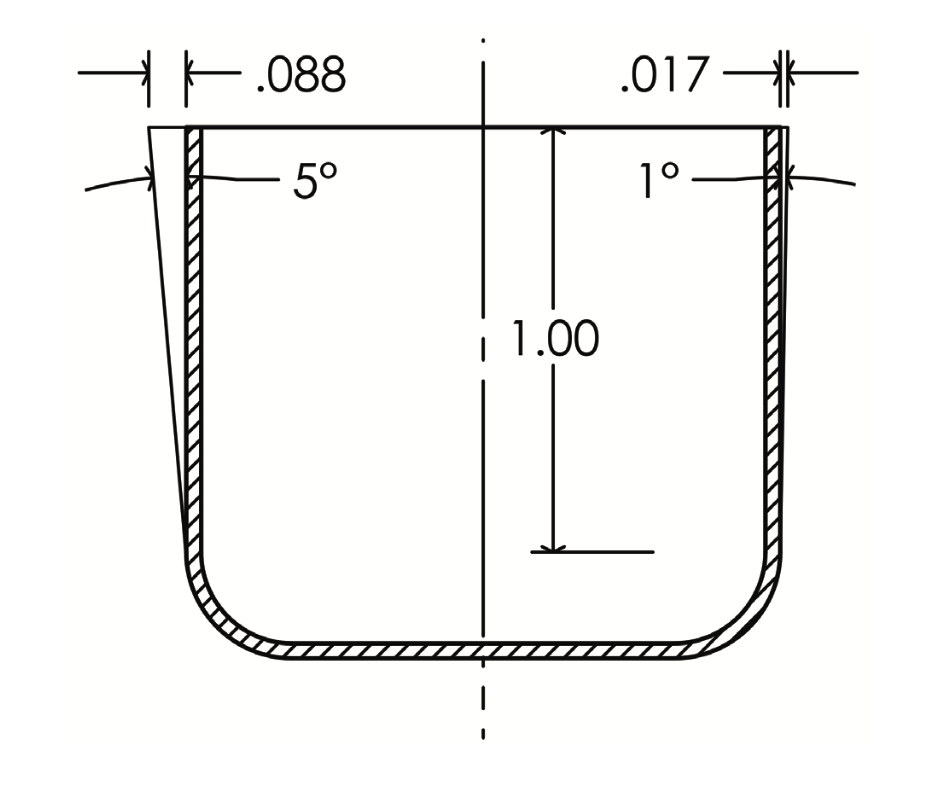

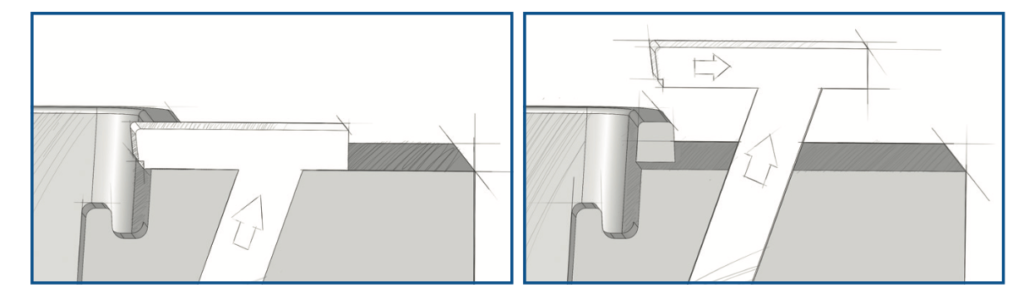

As a general rule if you have a rougher surface texture or deep feature you will need larger draft angle. Vacuum forming s cost efficient nature is why it is typically the go to production method for experts. Ensure material distribution with radii. In pressure forming however both vacuum pressure and positive air pressure pull and push the heated resin even more tightly against the surface and into the recesses of the mold.

It can help prevent issues with de moulding which can be costly to rectify. The right draft angle. If you re forming over a male mould add draft angles of at least 3 degrees but if you re forming into a female mould add draft angles of at least 5 degrees.